As fluid handling, efficiency, and reliability are of paramount importance. One solution that has gained widespread recognition for its versatility and performance is the AODD Pump. Here we will delve into the art of efficient fluid transfer by decoding the inner workings of these pumps. By exploring their features, applications, and benefits, we aim to shed light on why these pumps have become a go-to choice for industries around the world.

Understanding Air Operated Double Diaphragm Pump

The Working Principle:

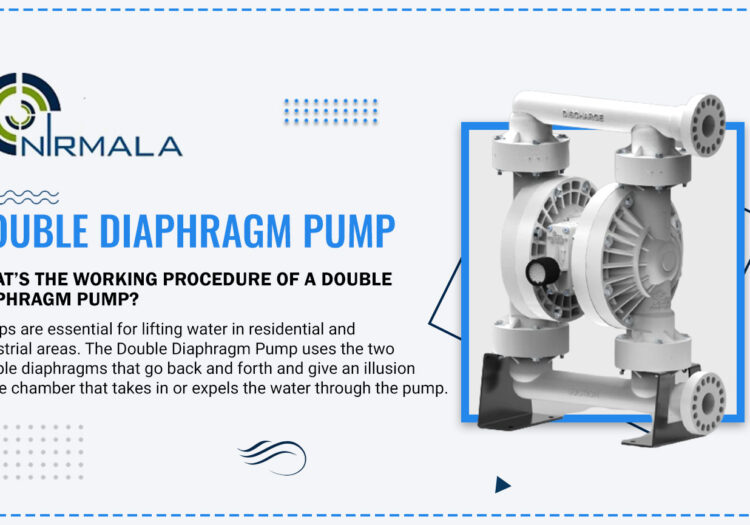

An Air Operated Pump also known as an air-driven diaphragm pump, utilizes compressed air to transfer fluids. The pump operates through the reciprocating motion of flexible diaphragms, creating a pulsating action that draws in and discharges the fluid.

Key Components and Construction:

These pumps consist of two pumping chambers equipped with flexible diaphragms, which are connected to a central air distribution system. The compressed air alternates between the chambers, causing the diaphragms to move back and forth, effectively pumping the fluid. The pumps are known for their robust construction and resistance to corrosive fluids, thanks to materials like thermoplastics, metals, and elastomers.

Features and Advantages:

- Versatility and Adaptability: These pumps excel in a wide range of applications, including chemical processing, wastewater treatment, food and beverage, pharmaceuticals, mining, and many more. Their ability to handle various fluids, from viscous and abrasive liquids to shear-sensitive substances, makes them highly versatile.

- Self-Priming and Dry-Run Capabilities:

They are self-priming, meaning they can evacuate air and begin pumping fluid without the need for external priming. Additionally, these pumps can handle dry running without damage, making them ideal for applications where occasional dry operation is inevitable.

- Enhanced Efficiency and Safety:

These pumps offer precise flow control, allowing users to adjust the flow rate easily. Their positive displacement design ensures consistent flow regardless of discharge pressure changes. Furthermore, AODD Pump Suppliers in India make sure they are intrinsically safe, as they do not require electricity and can operate in hazardous environments.

- Simple Maintenance and Easy Repair:

All pumps are designed for straightforward maintenance and repair. Their modular construction allows for easy replacement of diaphragms, valves, and other components, minimizing downtime and reducing maintenance costs.

Key Points while Choosing the Right AODD Pump:

When choosing the right pump for your specific application, it’s important to consider several key points.

A. Assessing Application Requirements:

To select the appropriate pump, consider factors such as fluid compatibility, flow rate, discharge pressure, temperature, and solids handling capability. Evaluate the specific needs of your application to ensure the pump’s specifications align with the requirements. Assess the compatibility of the pump materials with the fluid being pumped. Consider the chemical composition, viscosity, temperature, and abrasive properties of the fluid to ensure the pump is resistant to corrosion, degradation, or damage.

B. Quality and Reliability:

Partner with reputable manufacturers known for producing high-quality Air Operated Diaphragm Pumps. Thoroughly research their track record, customer reviews, and certifications to ensure the reliability and longevity of the chosen pump.

C. Expert Guidance:

Consult with industry experts or pump suppliers who can provide technical expertise and guidance in selecting the most suitable pump for your application. Their knowledge can help optimize pump selection and overall system performance.

D. Flow Rate and Pressure Requirements:

Determine the required flow rate and operating pressure of your application. This will help you select an AODD pump with the appropriate capacity and capability to meet your specific needs.

E. Pump Size and Portability:

Consider the available space and portability requirements in your facility. Choose a pump size that fits your installation area and allows for easy maintenance and mobility if necessary.

F. Solids Handling Capability:

Evaluate whether your application involves pumping liquids with suspended solids or abrasive particles. Select a pump with sufficient solids handling capability to prevent clogging or damage to the pump components.

G. Air Consumption: Understand the air consumption requirements of the AODD pump. Ensure that your air supply system can provide the necessary air pressure and volume to operate the pump efficiently.

H. Efficiency and Energy Consumption: Assess the pump’s efficiency and energy consumption to optimize your operational costs. Look for pumps with high-efficiency ratings and low air consumption to minimize energy usage.

J. Maintenance and Serviceability: Evaluate the ease of maintenance and availability of spare parts for the chosen AODD pump. Opt for pumps that are easy to access, disassemble, and clean, with readily available spare parts and service support.

Conclusion:

AODD Pump Manufacturers in India has revolutionized fluid transfer in a myriad of industries by offering unmatched versatility, reliability, and efficiency. By decoding their inner workings and understanding their benefits, applications, and selection criteria, industrial professionals can harness the art of efficient fluid transfer and propel their operations to new heights. Embrace the power of air-operated pumps and unlock enhanced productivity and performance in your fluid handling endeavours with Nirmala Pumps and Equipments.

Nirmala Pumps & Equipments

Nirmala Pumps & Equipments is an Indian company that manufactures and supplies pump systems, valves, strainers, and pneumatic pumps since 1989. We provide services to different industries, both domestically and internationally, such as citrus, distilling, wastewater treatment, and petroleum.