Foot valves are beneficial because they prevent damage to water pumps that can occur due to dry runs, as well as stopping wastage of energy.

These valves are a necessary part of all pumping systems.

In situations where the liquid is being pumped from sumps on the ground to liquid tanks on top of buildings, it’s necessary to use powerful electric pumps. As an example, these pumps typically work by producing a suction that forces the water upward through the piping system to the desired tank.

While the pump is running, there’s a constant column of water in the pipe as a result of the suction that’s created. But when the pump is shut off, the suction disappears, and gravity affects the water column. If there wasn’t a foot valve in place, the water would flow down through the pipe, back to its original source. The pipe would be left empty of water, instead filled with air.

Then, when the pump is turned back on, the air that is in the pipe will oppose the flow of water, and even though the pump is on, water will not move through the pipe. When this happens, it causes dry runs, which can damage the pump if it isn’t addressed quickly.

The foot valve solves this problem effectively. It doesn’t allow any backflow of water when the pump is turned off. The pump stays primed for the next time it’s used.

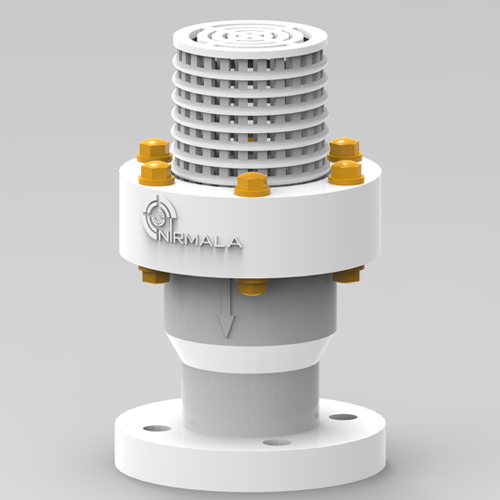

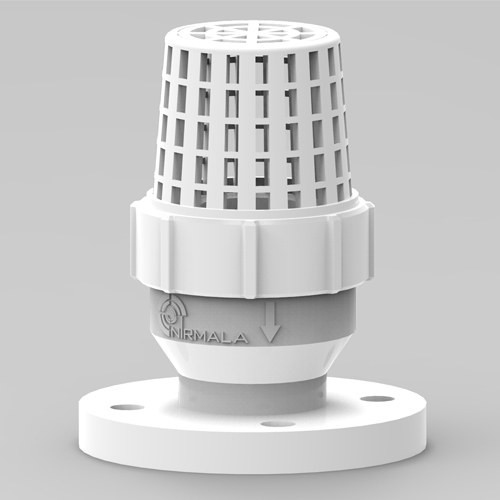

To satisfy the wide range of industrial applications we have both Ball type and flap type foot Valves.

MOC available are both in PP and PVDF